Cogeneration: Power to the people

The Madhouser Gencar shows how to get reliable off-grid electricity and hot water - for $5 of fuel a week.

Our gencar has never been more than a rough, experimental 'pilot project' to demonstrate the cogeneration concept, to find what problems the concept has, and to devise solutions if we could. With a more suitable engine we could have gotten twice the electricity and twice the heat recovery while burning half the fuel we burn now.

The cogen plant has provided electricity and hot water all day long, every day, for four years. What problems have arisen have been solvable with basic electrical knowledge and simple hand tools and it has become an increasingly reliable and economical unit to operate.

Getting two or more uses from your fuel energy is the way to go with the limited supplies of solar biomass fuels. Trans-estrified fats, ethyl alcohol, biogas, charcoal gas, can all provide for essential needs if used wisely.

The Madhouser cogeneration system saves people huge amounts of money and labor. By harvesting the great amounts of heat energy an internal combustion engine normally wastes, we're able to have on hand at all times a 30 gallon tank of hot water which can be used for washing clothes or dishes or bathing. This saves the building of many fires and the cutting and burning of much wood.

One person was heating his water with propane, bought in one pound cylinders, which normally cost three dollars. We've arranged about three month's worth of empty cylinders from this one man in front of our hot water tank. We simply reroute engine coolant lines that would go to the car heater, to a heat exchanger in the insulated water tank. Once heated, insulation in the tank walls can keep the water hot for two days.

Electricity 1000 times cheaper!

Every run of the gencar stores in golf cart batteries 100 amp-hours of electricity at 12 volts - 1.2 kilowatt-hours of energy.

This costs a dollar in gas to run the motor and a dollar in upkeep, or $1.66/ kilowatt-hour. If you count heat recovered in the water tank to equal electricity to run a water heater, it works out to about 25 cents a kilowatt-hour. This is well below some of the rates charged by electric companies in California recently.

An alkaline D-cell costs a dollar and gives half an amp-hour of current at 1.5 volts. This works out to $1300.00 a kilowatt-hour.

Even watching a little TV that gives a few hours service on 8 D-cells can take a homeless person broke. That and using a flashlight can go through $20 worth of batteries a week. With our system six or eight people can play their radios, watch a TV, run a little electric fan on summer nights, or have a light when they need it.

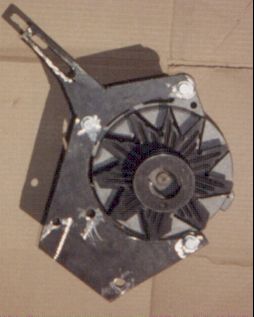

We made a flat steel plate that enabled us to use existing mounting bolt holes on the engine to install a second alternator. This put the alternator pulley in the same plane with the pulley of the original alternator so we could run both with the same belts. We were able to make a pattern and cut this shape out of a 3/16 piece of steel stock using an abrasive blade on an ordinary skilsaw. The bolt holes were drilled in it using a 3/8 hand drill.

Building our powerplant with hand tools without a machine shop kept us true to the principles of 'guerrilla' manufacturing, that is, it could be built anywhere with very little capital investment.

The final configuration of our generator system. Two alternators run by double belts gave us higher battery charging voltage and current. We got more useable electricity for the gas we burned. We proved two inexpensive alternators running in parallel run like one big, expensive one. If two will run this way, so will three or four.

#4 high quality copper cables, available in welding supply stores, transmit power efficiently within our generator. We also use these low resistance cables, instead of the car body, to provide the ground side of the circuit, avoiding many of the electrical problems that plague automobiles.

We learned as time went on that only the lowest resistance, most reliable wiring connections would be good enough. The connections at the battery posts gave the most problems because of corrosion.

Learning to safely solder connections between our wiring system and the batteries themselves was our most important achievement, as this is a problem throughout the alternative energy industry.

We got tired of fighting with electric cooling fans that wouldn't move enough air and always failed after a few months. We installed a mechanical flex-fan- backwards. This way it acts as a speed brake and limits motor speed as the system batteries charge up and require less power. Lower motor speeds save fuel, lubricating oil, and wear on the motor. A smaller motor would have been easier to regulate and use less fuel, but we had to use what we had.

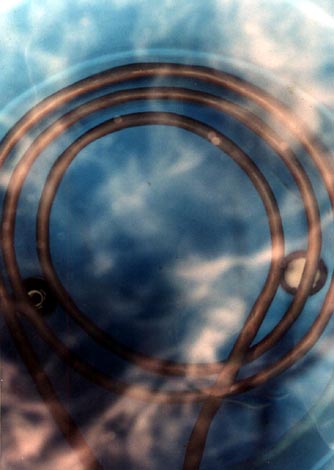

The Mad Houser cogen plant stores waste heat from the generator in the form of hot water, which is available on demand and can be expected to be at least warm for two days after a one hour generator run. The tank containing the water is insulated and features a heat exchange coil to heat the water. When the generator runs, hot motor coolant is circulated through the heat exchange coil by the engine water pump. The heat exchange coil consists of 5/8 inch soft copper tubing, which can be bought in hardware stores, and which keeps the motor coolant (containing antifreeze) completely seperate from the hot water people use for bathing and washing clothes and dishes.

If people are to readily transfer heat energy from one medium to another, they need to design and use what engineers call a 'heat exchanger'. The heat exchanger in our cogen plant transfers heat from hot motor coolant containing antifreeze to water people use for bathing and washing dishes without mixing the two liquids. Heat conducts readily through the thin copper walls of the heat exchange coil, shown here. Looking like an electric heating element, the coil is actually 5/8 soft copper tubing obtained in a hardware store, which can readily be bent into complex shapes.

This heat exchanger has transfered heat equivalent to several hundred gallons of gasoline, enabling us to provide clean hot water continuously on demand the past four years.